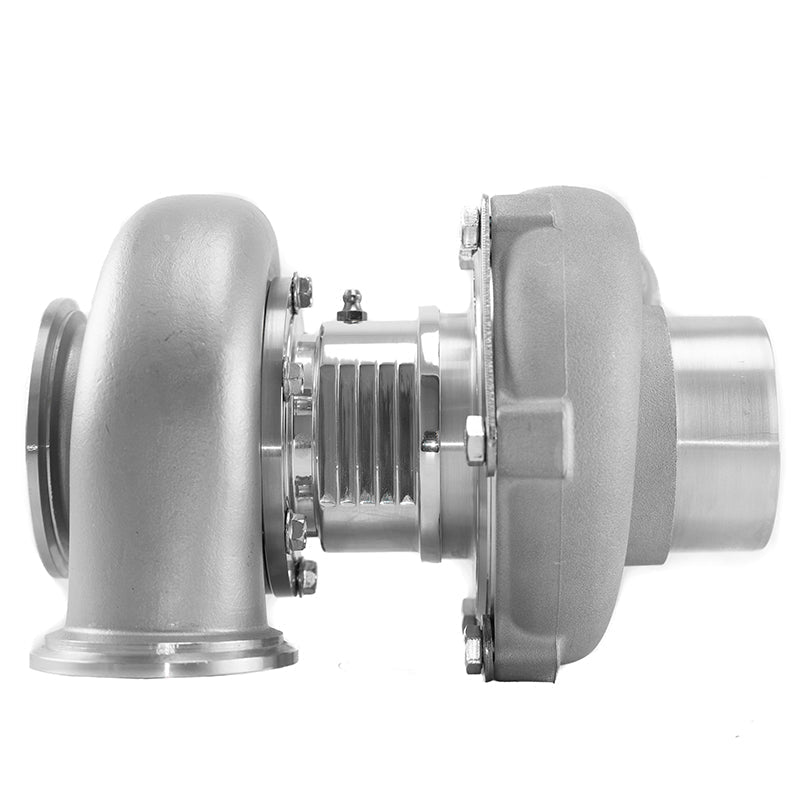

Lubrication is crucial for turbochargers spinning at super - high speeds. Traditionally, engine oil has been used to lubricate turbocharger bearing systems, but it comes with limitations like restricted mounting options, susceptibility to contaminants, leakage, and smoking. Comp Turbo revolutionized the game by introducing the world's first production oil - less turbocharger! The patented CTR Oil - Less Turbochargers use a Triplex Ceramic triple ball bearing system, lubricated by a top - quality non - channeling grease. The air - cooled model has an internal air passage behind the compressor wheel for cooling instead of a water jacket. Without the need for oil or water lines and with a Zerk fitting for easy servicing, these turbochargers are perfect for low, mid, or remote mount setups. Comp Turbo ball bearing turbochargers have a patented triple ball bearing design with 99% mechanical efficiency. They offer a faster transient response than the industry - standard dual ball bearing system due to less friction. This significantly improves response times and boosts power output. Our patented Triplex Ceramic bearing system is housed in a billet aluminum housing, making our turbochargers 5 to 12 pounds lighter on average. All our turbochargers are proudly made in the USA and feature the latest R - Line technology. The CTR 7/14 veined billet slim hub extended tip compressor wheel and CTR slim hub lightweight turbine wheel are part of our most advanced rotor technology. Features: • Titanium Bullet Nose • Fully Rebuildable/Upgradeable • Anti - Surge Compressor Housing • CTR Compressor and Turbine Wheel • No need for oil and water lines • Can be mounted in any orientation CTR Compressor Wheel Technology: The CTR - line turbochargers have a 7 - 14 vaned compressor wheel with the latest compressor design. It has a small - diameter hub for more intake airflow and an extended tip for better efficiency at high pressure ratios. The R - line design can produce higher boost pressures at high engine speeds and increase engine HP output by up to 15%. CTR High Flow Turbine Technology: The CTR Turbine wheels have 25% lower inertia, leading to quicker rotor acceleration. Their slim hub and thin blade design maximize flow capacity, 30% more than the prior GT style Turbine wheel. With minimal leaving velocity, these wheels offer higher turbine efficiency and a greater flow range. Turbochargers are built to order and take 3 to 5 weeks to deliver.

Using your Triplex Ceramic Oil - Less and Air - Cooled Turbocharger is straightforward. First, you can mount it in any orientation you need, which is super convenient. Since it doesn't require oil or water lines, installation is a breeze. When your turbocharger is up and running, enjoy the fast response and increased power it provides. For maintenance, the Zerk fitting makes servicing easy. Just make sure to follow the recommended servicing schedule. And remember, these turbochargers are fully rebuildable and upgradeable, so if you need to make changes in the future, you can. Also, keep in mind that these turbochargers are built to order, and it'll take 3 to 5 weeks for delivery, so plan ahead.